Introduction

A poultry pellet making machine is a specialized mechanical device designed to process raw feed ingredients into uniform, nutritionally balanced pellets suitable for chickens. These machines are widely used in small farms, commercial feed mills, and integrated poultry operations to improve feed efficiency, reduce wastage, and ensure consistent nutrient intake.

Poultry feed machines are essential in modern poultry farming due to the increasing demand for meat and eggs globally. They help farmers convert grains, protein meals, and additives into pellets of specific sizes appropriate for chicks, broilers, layers, or breeder flocks.

History of Poultry Feed Pelletization

The concept of pelleted poultry feed dates back to the early 20th century, when industrial agriculture began to adopt mechanized feeding systems. Initially, poultry were fed mash or loose grains, leading to selective feeding and inconsistent nutrient intake.

With the advent of mechanical pellet mills, feed producers could produce consistent, compact feed that minimized waste and improved growth rates. Over the decades, advances in metallurgy, motor technology, and die design allowed machines to handle a wider variety of raw materials, including fibrous components like soybean hulls or rice bran.

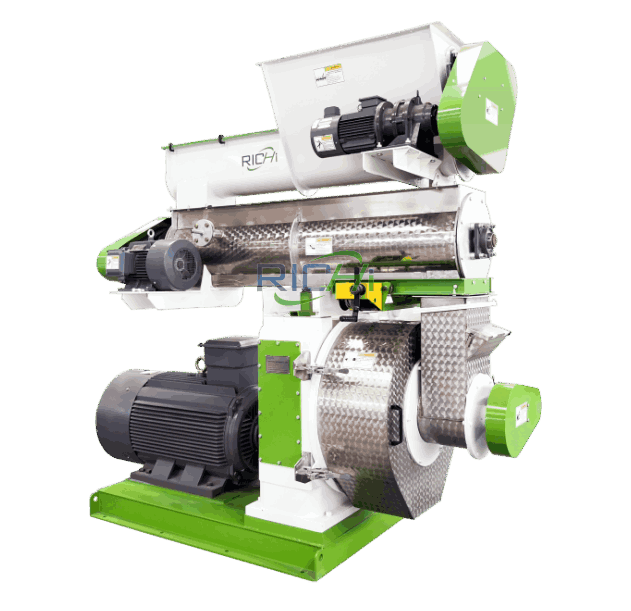

Structure and Components of a Poultry Feed Pellet Machine

A typical pellet making machine for poultry feed consists of several core components:

Feeding system: Ensures uniform delivery of raw materials into the pelletizer

Conditioner: Adds moisture and heat to soften ingredients, improving pellet quality

Pelletizing chamber: Houses the die and rollers that compress feed into pellets

Drive system: Motors, gearboxes, and couplings provide necessary torque

Discharge and cutting mechanism: Cuts pellets to the desired length before cooling

Machines are designed to withstand continuous operation while producing uniform, durable pellets suitable for poultry of various ages.

Working Principle

The working principle of a pellet making machine for poultry feed is based on mechanical extrusion. Raw feed ingredients are first fed into the machine and mixed in a conditioner with steam or water to enhance plasticity.

Inside the pelletizing chamber, rollers press the conditioned feed against the die. Pressure forces the feed through the die holes, forming cylindrical pellets. Knives outside the die cut the pellets to the desired length. The finished pellets are then cooled and hardened for storage or packaging.

Common Raw Materials

Pellet making machines for poultry feed are designed to process a variety of ingredients:

Cereal grains: corn, wheat, barley, sorghum

Protein meals: soybean meal, cottonseed meal, fish meal

By-products: wheat bran, rice bran, distillers dried grains

Additives: vitamins, minerals, and enzymes

Fibrous ingredients: alfalfa meal, grass powder (for adult layers or breeder flocks)

The machine’s versatility allows farmers to use locally available ingredients and optimize feed formulations for growth, egg production, or reproduction. https://richipelletizer.com/poultry-feed-pellet-machine-price/

Types of Pellet Making Machines

1. Flat Die Pellet Machines

Compact design, suitable for small farms

Lower production capacity and price

Easy to operate and maintain

2. Ring Die Pellet Machines

Higher capacity and efficiency

Long service life

Often used in commercial feed mills

Machines from reputable manufacturers like RICHI are optimized for poultry feed pellet production

Pellet Size and Poultry Type

The diameter and length of pellets are chosen based on the type and age of poultry:

Chicks: 2–3 mm

Broilers: 3–4 mm

Layers / adult chickens: 4–6 mm

Proper pellet size ensures optimal feed intake, minimizes selective feeding, and supports uniform growth.

Factors Influencing Pellet Making Machine Price

Several factors affect the pellet making machine for poultry feed price:

Production capacity: Higher throughput machines cost more due to larger motors and reinforced structures

Die type and quality: Ring die machines are more expensive than flat die machines

Automation level: Automatic feeding, lubrication, and monitoring systems increase cost but reduce labor

Raw material adaptability: Machines handling a wider range of ingredients generally have higher prices

Build quality: High-strength alloy dies and rollers improve longevity, increasing upfront investment Next page

Applications in Poultry Farming

Pellet making machines are used across a variety of poultry operations:

Broiler farms: Support rapid growth and feed conversion efficiency

Layer farms: Provide consistent nutrition for egg production

Breeder operations: Maintain reproductive performance

Feed mills: Produce large-scale commercial poultry feed for regional or national distribution

Pelletized feed improves digestibility, reduces feed wastage, and ensures a uniform nutrient intake across flocks.

Operating Costs and Maintenance

While initial machine cost is important, operating costs must also be considered:

Electricity consumption

Labor requirements

Routine maintenance

Die and roller replacement

Well-maintained machines can last many years. Suppliers such as RICHI Equipment provide technical guidance to optimize maintenance schedules, ensuring consistent performance and longer service life.

Environmental and Sustainability Considerations

Pellet making machines for poultry feed support sustainable farming:

Reduce feed wastage and dust

Allow use of agricultural by-products

Improve feed conversion ratios, lowering overall resource use

Energy-efficient models minimize electricity consumption, contributing to environmentally friendly poultry production.

Global Market Trends

Demand for poultry feed pellet machines is growing worldwide:

Asia, Africa, and Latin America show the highest growth rates due to expanding poultry production

Prices vary regionally due to import duties, shipping, and local manufacturing capacity

Technological improvements and competition among manufacturers, including RICHI, help keep machines affordable for small and industrial users

Conclusion

A pellet making machine for poultry feed is an essential tool in modern poultry farming, converting raw feed into uniform pellets that improve growth, egg production, and overall feed efficiency. Understanding the factors influencing price, including capacity, die type, automation, and raw material adaptability, helps buyers select the most cost-effective machine for their operations. From small-scale farms to industrial feed mills, these machines are vital for sustainable and profitable poultry production. Chicken feed making machine south africa

-150x150.jpg)

.jpg)