The global poultry industry continues to expand as demand for chicken, eggs, and processed poultry products rises steadily. Feed cost and feed quality remain the most critical factors affecting poultry farming profitability. A modern poultry feed production line—representing a complete set of poultry feed processing and manufacturing equipment—plays a vital role in producing nutritionally balanced, cost-effective, and high-quality feed.

This article provides a comprehensive and SEO-friendly overview of poultry feed production lines, covering raw materials, process flow, equipment configuration, advantages, automation, and key selection considerations.

Overview of Poultry Feed Production

Poultry feed accounts for a major portion of total production costs in broiler and layer farming. Traditional manual mixing methods often lead to uneven nutrition, higher waste, and unstable performance. A professional poultry feed production line enables feed mills and poultry farms to produce standardized feed with consistent quality and improved feed conversion ratios.

Modern poultry feed manufacturing plants are designed to support:

- Broiler feed production

- Layer feed production

- Chick starter and grower feed

- Mash feed, crumble feed, and pellet feed

Related long-tail keywords include poultry feed production line manufacturer, automatic poultry feed production line, poultry feed pellet production line, poultry feed manufacturing plant, and small-scale poultry feed production line.

What Is a Poultry Feed Production Line?

A poultry feed production line refers to an integrated system of machines working together to process raw materials into finished poultry feed. It is not a single machine, but a complete solution covering the entire production cycle—from raw material intake to final packaging.

Depending on production requirements, a poultry feed production line can produce:

- Poultry feed pellets

- Poultry mash feed

- Crumble feed for chicks

- Customized feed formulas for different growth stages

The system can be configured for small farms, medium feed mills, or large industrial poultry feed factories.

Common Raw Materials for Poultry Feed

A major advantage of a poultry feed production line is its ability to process a wide range of raw materials, including:

- Corn, wheat, and sorghum

- Soybean meal and sunflower meal

- Rice bran and wheat bran

- Fish meal and meat bone meal

- Vegetable oils and fats

- Vitamin and mineral premixes

By accurately controlling formulations, poultry feed manufacturing plants can optimize nutrition while managing raw material costs.

Process Flow of a Poultry Feed Production Line

A modern poultry feed production line follows a standardized and efficient process to ensure consistent feed quality and high productivity.

1. Raw Material Receiving and Cleaning

Raw materials are received in bulk and passed through cleaning equipment such as vibrating screens and magnetic separators. This step removes stones, metal, and impurities, protecting downstream poultry feed machines.

2. Crushing and Grinding

Hammer mills reduce grains to the appropriate particle size. Fine and uniform grinding improves digestibility and ensures better pellet quality in poultry feed pellet production lines.

3. Batching and Mixing

Automatic batching systems weigh each ingredient according to the feed formula. High-efficiency mixers ensure uniform distribution of nutrients, additives, vitamins, and minerals.

4. Pelleting

Pelleting is the core process of the poultry feed production line. The poultry feed pellet machine compresses mixed materials into durable pellets that reduce feed waste and improve palatability. Pellet size can be adjusted for broilers, layers, or chicks.

5. Cooling and Crumbling

Fresh pellets are hot and moist after pelleting. Counterflow coolers reduce temperature and moisture, improving pellet hardness and storage stability. For chick feed, pellets can be crumbled into smaller sizes.

6. Screening and Packaging

Finished feed is screened to remove fines and then automatically weighed and packed into bags or bulk containers.

(article: https://pelletisingmachine.com/animal-feed-machine/)

Key Advantages of a Poultry Feed Production Line

Investing in a professional poultry feed production line offers several important benefits:

1. Improved Feed Efficiency

Pelleted and crumbled feed improves feed intake uniformity and reduces selective feeding, leading to better feed conversion ratios.

2. Stable and Consistent Quality

Automated batching and controlled pelleting ensure consistent nutrition in every batch of poultry feed.

3. High Production Efficiency

Automatic poultry feed production lines support continuous operation with stable output and reduced labor requirements.

4. Flexible Capacity and Configuration

From small-scale poultry feed production lines to large industrial plants, systems can be customized to meet specific production needs.

5. Lower Long-Term Operating Costs

Modern poultry feed manufacturing equipment is designed for energy efficiency, durability, and reduced maintenance.

Equipment Configuration of a Poultry Feed Production Line

A complete poultry feed production line typically includes:

- Raw material cleaning system

- Hammer mill or grinder

- Automatic batching and mixing system

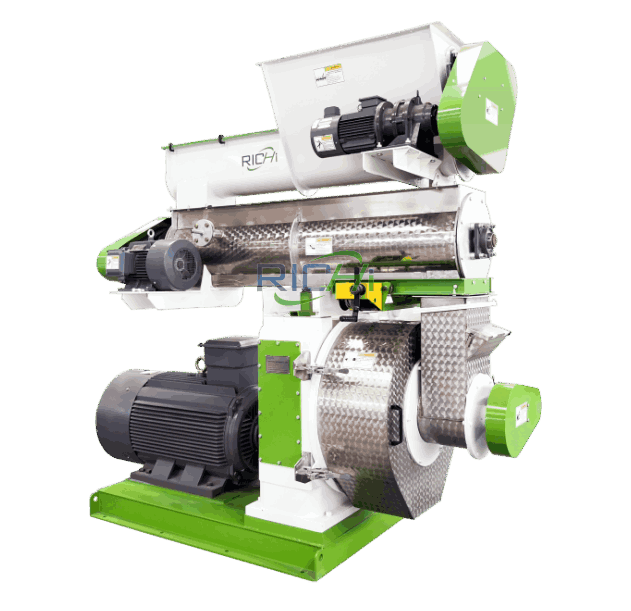

- Poultry feed pellet machine

- Counterflow cooler

- Crumbler (optional)

- Vibrating screen

- Automatic packing system

Equipment layout and configuration can be customized based on plant space and output requirements.

Automation and Control Systems

Modern poultry feed production lines increasingly adopt PLC control systems that enable:

- Centralized operation and monitoring

- Accurate feed formulation management

- Reduced human error

- Stable and repeatable production performance

Automation is essential for large poultry feed manufacturing plants aiming for consistent quality and efficient operation.

Application Scenarios

Poultry feed production lines are widely used in:

- Commercial poultry feed mills

- Large broiler and layer farms

- Poultry breeding and integration projects

- Agricultural cooperatives

On-site feed production allows poultry producers to reduce feed costs, improve feed quality, and enhance supply stability.

How to Choose the Right Poultry Feed Production Line

When selecting a poultry feed production line, consider the following factors:

- Target poultry type (broiler, layer, chick)

- Feed form requirements (mash, pellet, crumble)

- Required production capacity and future expansion

- Equipment reliability and maintenance cost

- Supplier experience and after-sales technical support

A reliable poultry feed production line should deliver stable performance, consistent feed quality, and long-term operational reliability.

Future Trends in Poultry Feed Production

As the poultry industry continues to modernize, poultry feed production lines are evolving toward:

- Higher automation and digital control

- Improved energy efficiency

- Greater formulation flexibility

- Integration with smart farm management systems

These advancements help poultry producers remain competitive while meeting increasing demand for safe and traceable feed.

Conclusion

A professional poultry feed production line is the backbone of efficient and profitable poultry farming. By integrating crushing, mixing, pelleting, cooling, and packaging into a single automated system, poultry feed production lines ensure consistent feed quality, optimized nutrition, and controlled production costs. Whether for small farms or large industrial feed mills, choosing the right poultry feed production line is a critical step toward long-term success in the poultry industry.

-150x150.jpg)

.jpg)